Concrete cutting may seem extremely dangerous and ridiculously difficult – and you’d be right! If you start playing with concrete cutting blades and saws without knowing what you’ve just got yourself into, you may run into some potentially deadly problems: kickback, locking-in, hazardous dust, and worse… and choosing the wrong blade can be the most serious mistake of all.

You may think concrete is just concrete, but no: all concrete is not created equal! There are different thicknesses, consistencies, compressive strengths, aggregate sizes, and the list goes on. For an experienced pro, it’s just another day at work. But if you don’t know how to cut concrete or how to account for the many variables at play, you won’t know how the blade’s thickness, segment width and characteristics will seriously affect the ease, precision, effectiveness and cleanliness of the cut.

There’s really a lot of markedly different concrete saw blades out there? Oh yes, there are! With our extensive experience concrete cutting in Melbourne, let’s introduce the most common blades.

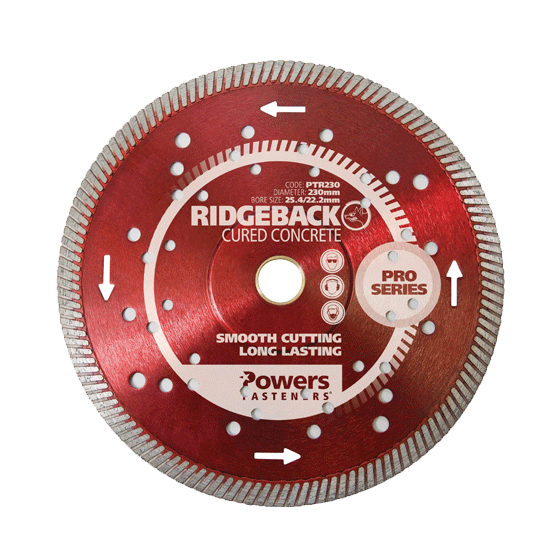

1. The turbo-rim blade

Every great concrete cutter will use a turbo-rim blade just about every day. It’s a prime example of an aggressive, serrated-rim diamond blade that chews through the roughest and hardest of concrete and bricks in no time for a smooth finish. The blades are made using synthetic diamond crystals, creating an extremely strong cutting surface that is safer than the abrasive blade that we will discuss later.

2. The segmented blade

Also featuring diamond edges, the segmented concrete blade gets its name from the ‘gullets’ – the spaces between the blade’s segments. These gullets work to efficiently clear the dust and cool the blade, as well as preventing the development of cracks due to a bit of in-built flexibility.

3. The continuous rim

It’s easy to spot a continuous rim cutting blade because of the consistent (or continuous!) nature of the rim. However, because it lacks the segments or cut-outs, it’s most suitable for wet cutting concrete due to the less effective cooling and the presence of debris. Why, then, would you use it? Because the cut itself is of extremely high quality, and perfect for materials like granite, marble, porcelain or tile. The cutting takes longer than with the more versatile wet-dry blades, though.

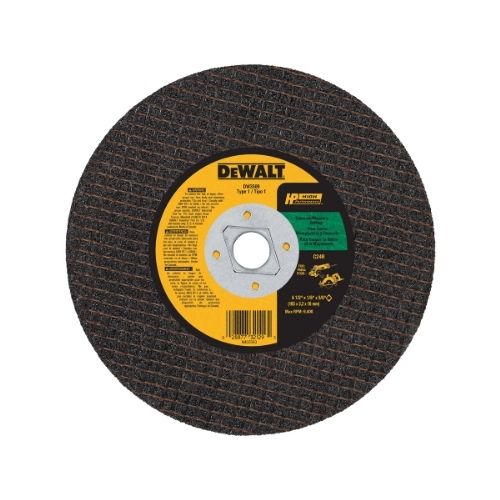

4. The abrasive blade

The best concrete cutting professionals will also be familiar with the abrasive cutting blade, which are made from hard compounds like silicon carbide and aluminium oxide. But these same pros will probably tell you that wear is a problem, not to mention the likelihood of blade failure and dangerous blade dusts.

5. The circular saw blade

Never forget: cutting concrete is hard and dangerous – and mistakes can not only be damaging and expensive, but absolutely deadly! That’s exactly why a simple call to Hard Core VIC, concrete cutting and drilling professionals, is probably your best bet if you have some concrete cutting that needs doing correctly and safely the first time … with the right blade for the job every single time! Get in touch with one of our most experienced, skilled and friendliest concrete cutters today to discuss your particular project.