Question: what word makes a concrete expert cringe? Answer: cracks. That’s because while the perfect driveway or path is a fine art, there’s no avoiding that it’s a material that expands and contracts along with the unavoidable fluctuations of temperature and moisture.

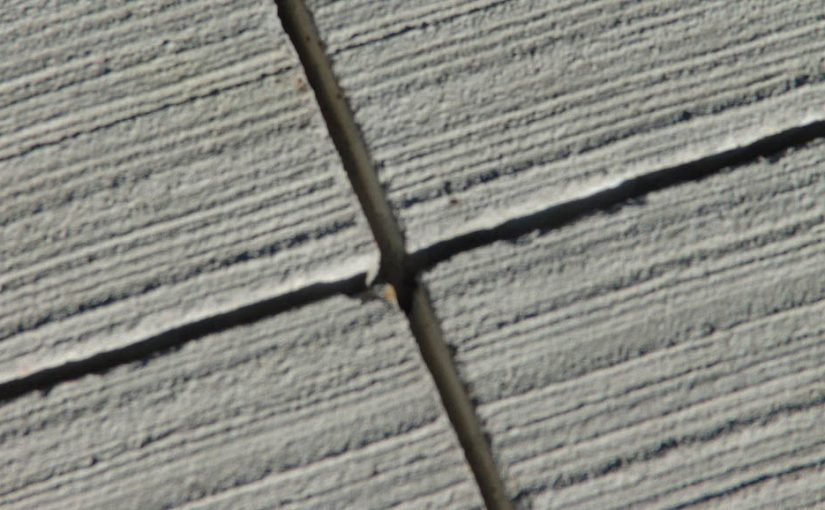

The solution? Concrete control joints, otherwise known as concrete expansion joints. When those slabs are poured, the strategic placing of these joints – usually clearly visible in any professionally-laid concrete – will relieve the expansion or movement stresses over the concrete’s life and hopefully avoid uncontrolled cracking. Or, in simpler terms, control joints in concrete are basically controlled cracks – on the smart concreter or concrete cutter’s terms.

But when are these concrete joints cut? Where are they cut? And how is the cutting done?

Let’s explore the WHEN, WHERE and HOW of concrete expansion joints:

1. When?

If you only start to think about concrete control joints once the concrete has started to crack, that’s really too late. Ideally, the joints are created when the concrete is poured, with the help of a special tool. But if they have to be cut into the slab once it’s down, it should be as soon as possible into the curing process. That’s because once it has completely dried, you risk ravelling – or severely disturbing – the particles of the concrete mix, especially if it’s being cut by a novice.

2. Where?

While too few concrete expansion joints won’t properly guard against the risk of cracking, too many can be unsightly and unnecessary – so it’s important to get it just right. If we’re talking about a standard slab depth of four inches, the concrete joints should be equally and strategically placed no more than 10-15 feet apart. As for how deep the joints should be cut, the rule of thumb is about a quarter of the slab’s thickness – so for that 4-inch slab, it should be an inch deep. Any shallower and it won’t do its job, and any deeper and you risk the integrity or strength of the slab. A cut that is too shallow can lead to unexpected cracking.

3. How?

It’s crucial that concrete joints are cut straight, so precision concrete cutting will follow a marked line. Next, you’ll need a good quality machine saw – not a manual one – with the blade set to the correct depth, and then they should be cleaned and filled to guard against corrosion and water intrusion. Those that truly know how to cut concrete will never twist the blade, let it spin in the cut, or fail to wear the right protective gear.

Always ask the experts about concrete control joints

Of course, the best people to ask about concrete expansion joints are the trained professionals with all the right training, experience and specialist equipment – just like the Melbourne concrete cutting and drilling experts at Hard Core VIC. No matter the size or complexity of your project, they’ll come up with the best, safest and most effective way to do your concrete cutting – so why not drop them a line today for a customised and affordable solution?